Liquefiable Soils

Liquefiable Soils

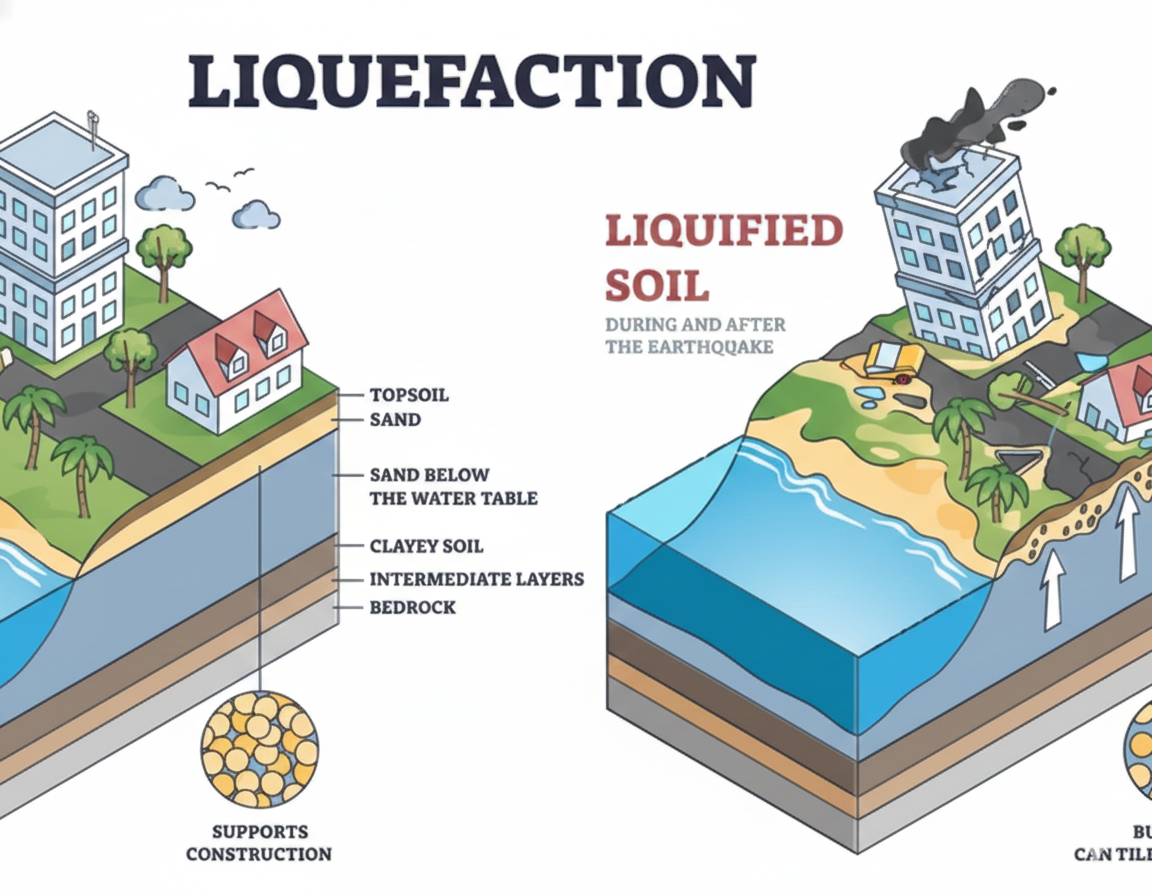

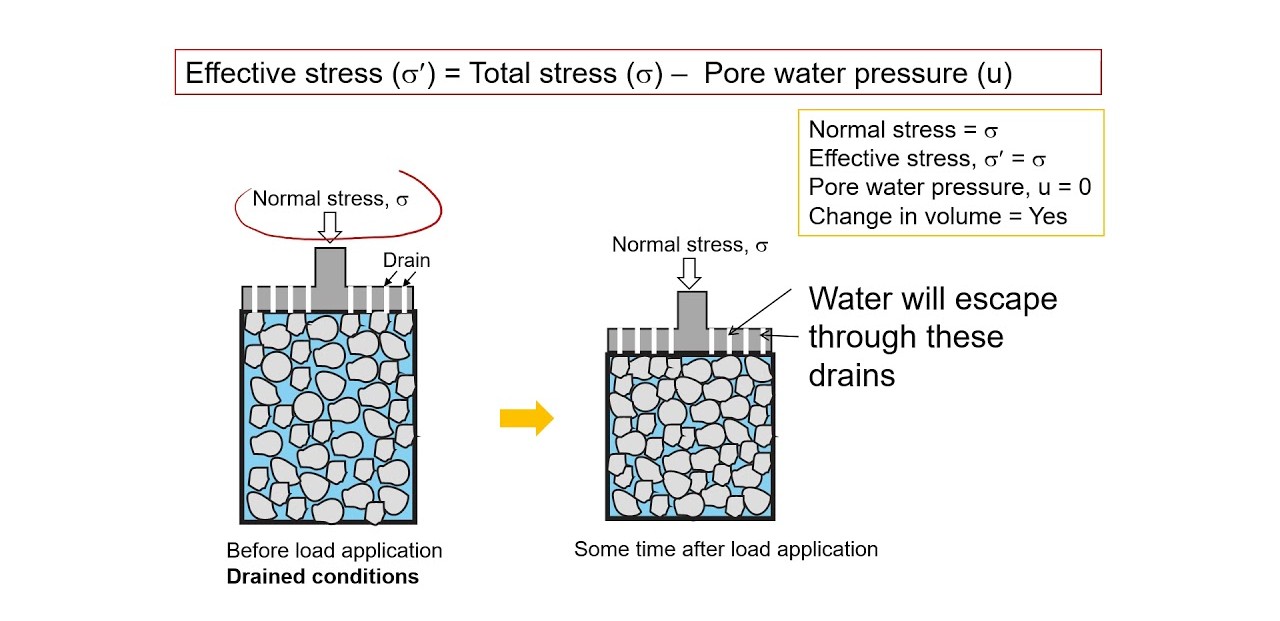

Liquefiable soils are loose, water-saturated sands or silty sands that can temporarily behave like a liquid during strong earthquakes. Under shaking, water trapped between soil particles builds up pressure, causing the particles to lose contact with each other. When this happens, the soil can no longer support structures above it. Buildings may tilt, roads may crack, and underground utilities may float or break.

A simple way to imagine liquefaction is to think of a bucket filled with sand and water. When the bucket is shaken, the sand grains momentarily lose their friction, allowing the water pressure to separate them. In real ground conditions, this loss of strength can happen in seconds during an earthquake.

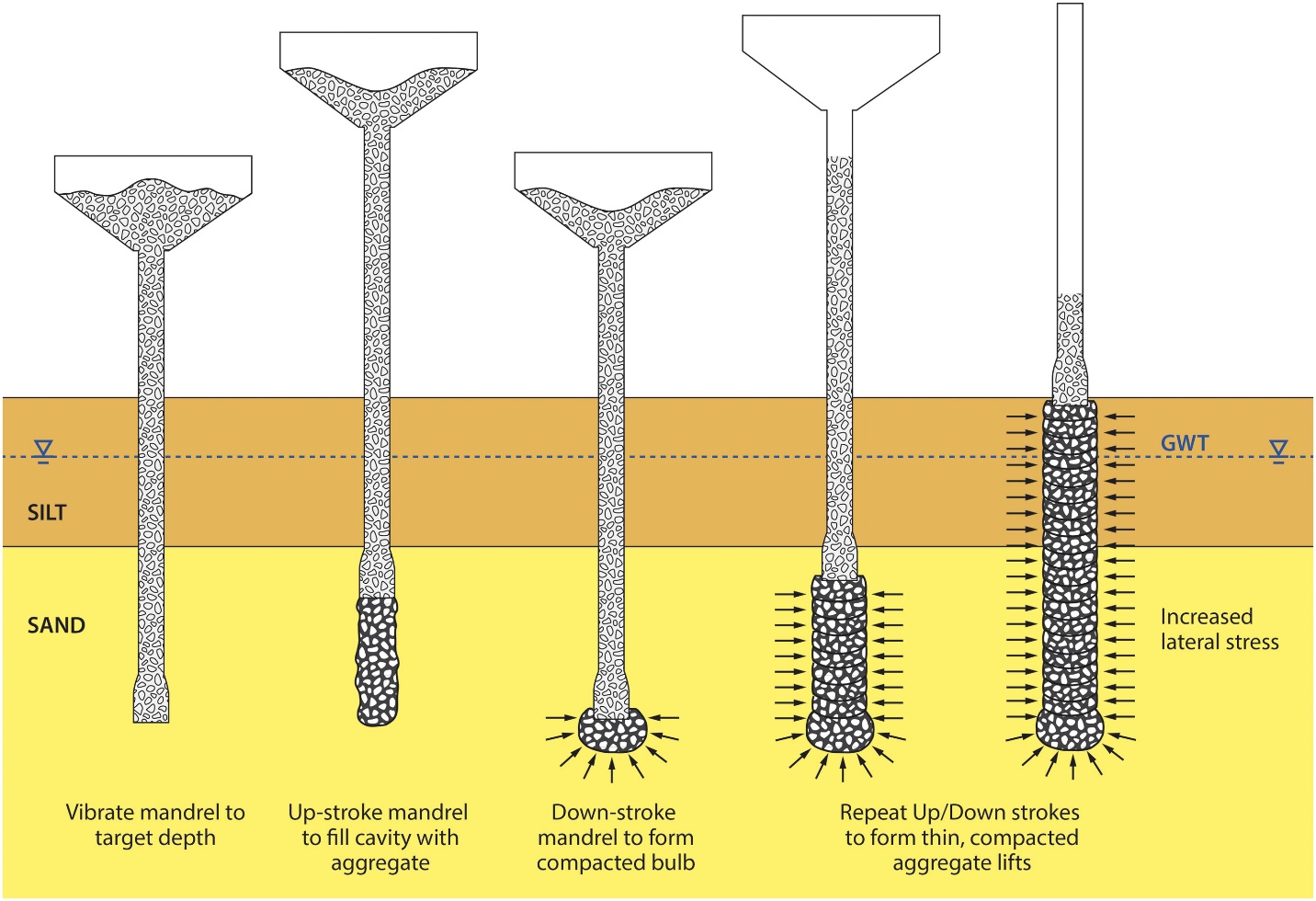

Rammed Aggregate Piers (RAPs) help address this problem by densifying and reinforcing the soil. RAPs are constructed by drilling holes and compacting crushed stone in layers using a high-energy ramming process. This process presses the surrounding soil grains closer together, making it harder for water pressure to build up during shaking. Additionally, the aggregate columns function as vertical drains, allowing excess water pressure to dissipate more quickly.

The improved ground behaves as a soil–pier composite system, where loads are shared between the natural soil and the stiff aggregate piers. This reduces settlement and significantly lowers the likelihood of liquefaction-related damage. For low- to mid-rise buildings and infrastructure, RAPs offer a practical and cost-effective solution for seismic ground improvement.