Emilio M. Morales, MSCE1]

1. INTRODUCTION

Of all activities in the realm of construction, nothing is as taken for granted as Earthworks. This is perhaps due to the misconception that “Soil is Soil” and that brute force alone will suffice in order to compact it. Nothing can be farther from the truth and numerous projects here and abroad have highlighted the important fact that soil can not be taken for granted as it can spell trouble in the construction site.

The purpose of this paper is to focus on the special characteristics of various soils and how best to harness this knowledge for optimum construction expediency.

2. THE NATURE OF SOILS

Soil is an aggregation or assemblage of particles which are the products of weathering or decomposition or rocks. They could have been weathered in place or transported by wind or water. The manner of deposition as well as the parent material dictate how the soil behaves when subjected to loading or other environmental factors.

Soil particles are either visible to the naked eye or are submicroscopic. Being a particulate material, soil behaves differently than say a solid material. Particulate behavior can be fully understood and once this is so, the treatment of problems involving soils and soil particles becomes simpler.

Soil is a structural material, but unlike other construction materials with known or predictable properties that could be specified at design stage, the engineer has to contend with what he will encounter in the field. Being a natural material, the soil will exhibit large variabilities even within the confines of a construction site.

In most instances, soils must be used “as-is” and “where-is” because of its great bulk and difficulty of transporting such large volumes.

Soil properties can also change with time and this must be anticipated. On the other hand, soil structure can also be altered by man in order to improve its characteristics significantly.

1) Soil Microstructure

Soil microstructure plays a very important part in the engineering behavior of soils. Soil structure can be altered or changed mechanically or chemically to produce desired characteristics for the project.

Soil can either be Coarse Grained (sands and gravels) or Fine Grained (clays and silts). In addition, these soils can be adulterated say by organic materials as to effectively alter its characteristic behavior.

2) Coarse Grained Soils

Sands and gravels constitute the bulk of these soils , the individual sand grains are visible to the naked eye and are “gritty” to the trouch. Clean sands behave as particulate material. They derive their strength chiefly from contacts between the individual sand grains which results in “friction”. Although the individual grains may not be fully in contact with each other. The large concentration of stresses at the contact points produces increased resistance to sliding one past the other.

Granular soil strength is essentially based on its Angle of Internal Friction “ϕ ” or its ϕ -Angle. The ϕ -Angle is not a unique value for a certain type of soil. Rather the ϕ angle is dependent on the degree of compactness of the soil and the confining pressure. The more compact and the more confined the granular soil is, the larger the ϕ -Angle.

Coarse grained soils in their loose state are sensitive to vibration and are thus easily compacted by vibratory means whether very dry or in saturated state.

When subjected to vibration, the loose coarse grained soils assume a denser packing and are thus compacted.

A similar effect although to slightly lesser degree can be achieved by totally saturating the loose sands with water. The loose packing collapses with flooding by water and the soil assumes a denser packing.

3) Fine Grained Soils

Fine grained soils such as clays and silts are generally submicroscopic and the individual soil particles are not readily visible to the naked eye.

Depending on the source or mineralogy, clays and silts may be plastic or non plastic.

Because of their very small size, the ratio of the surface area to the volume or mass is very very large and thus, surface activity due to electrochemical forces of attraction and repulsion come into play.

The shear strength or “cohesion” of these clays and silts are essentially derived from such forces and not through interparticle friction as one would suspect.

The individual soil particles known as platelets are seldom in contact as they are surround by highly bounded adsorbed water due to electrical forces of attraction and further by absorbed water which is weakly bonded.

Thus, the individual platelets slide one past the other because of these adsorb and absorbed layers of water.

Compaction of this soil is dependent chiefly in expelling this absorbed water and any air with it to reduce the interparticle distance between clay platelets so that the forces of attraction is increased due to the reduction in distance. The resulting strength due to electrochemical attraction is known as “cohesion”.

4) Intermediate Soils

Intermediate soils are either predominantly granular or fine grained but have fractions of the other as to significantly alter its characteristic behavior in its unadulterated state.

Data from tests made on sands used for molding indicate that its shear strength reaches a maximum and levels off with about 9 to 14% of clay depending on the clay mineral. If the clay content exceeds about 25% the strength degrades as the “Wedge Block” structure disappears and the individual sand or silt grain become separated and “floating” in a matrix of clay.2]

When sufficient clay is present to form a matrix enclosing coarser grained soils (normally 25-30% clay), the structure of the clay dictates the structural behavior of the soil.

3. MOISTURE DENSITY RELATIONSHIP OF SOILS

1) Proctor Moisture Density Relationships

R.R. Proctor is generally regarded as the originator of principles dealing with a rational approach to soil compaction.3]

Proctor felt the need to have a laboratory compaction test to control field compaction operations. His first decision was the selection of a laboratory compaction energy that would simulate compaction energies imparted by construction equipment in the field.

He accomplished this by specifying a 5.5 lb hammer dropping at 12 inches height on soil samples confined in a 4″ diameter steel mold. This came to be known as “Proctor Density”.

Later on, as the need for bigger airplanes and wheel loads developed during the war years, it was found that the original compaction requirements for airfields and highways would need to be increased.

Thus, higher compaction requirements resulted in the use of higher hammer energies in the laboratories. This came to be known as the “Modified Proctor” and the original Proctor Density became the “Standard Proctor Density”.

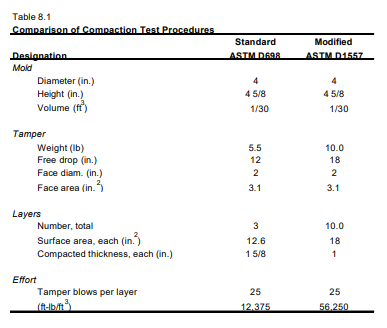

The table below shows the comparison between the two methods:

It can be seen from the foregoing that Modified Proctor energy is 4.51 times that of Standard Proctor Energy.

The two procedures came to be standardized as:

- ASTM D-698 – “Laboratory Compaction Characteristic of soil using Standard Effort (12,400 ft-lb/ft3)”

- ASTM D-1557 – “Laboratory Compaction Characteristic of soil using Standard Effort (56,000 ft-lb/ft3)”

There is a large difference in the compaction energy (and effort) needed in the laboratory and in the field to move from Standard to Modified Proctor Density.

Sometimes unknowingly or through ignorance, Engineers or the owner would specify the degree of relative compaction without specifying the reference as say: “to be compacted to 95% MDD” where: “to be compacted to 95% MDD based on ASTM D-698” would have been more appropriate.

4. IS THE PROCTOR MOISTURE DENSITY RELATIONSHIP APPRO-PRIATE FOR ALL SOILS?

This question does not often surface because there has been an implicit acceptance of this as the reference procedure for the compaction of all soils.

In point of truth, this is not so as relatively clean coarse grained soils are insensitive to moisture content except in the extreme ranges of being very dry or highly saturated. The concept of “Optimum Moisture Content” (OMC) therefore is not applicable to clean coarse grained “Free Draining” soils such as sands and gravels.

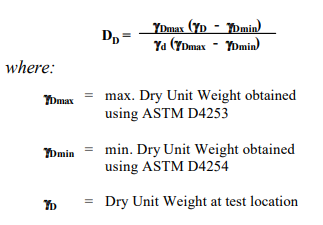

The compaction of clean coarse grained soils are not referenced against Proctor Densities (Standard or Modified) but rather on the concept of Relative Density (DR) using ASTM D4253 “maximum Index Density and Unit Weight of Soils using a Vibratory Table” and ASTM D4254 “minimum Index Density and Unit Weight of Soils and Calculation of Relative Density” and plugging the minimum and maximum values obtained therefrom to arrive at the reference relative density DD for the material.

Thus, the Relative Density of the soil as calculated is different from the Proctor Density.

Why then is Proctor Density still being specified for even clean sands? We can only guess that this is because of plain ignorance or probably the lack of test equipment for this test in the country. Although, relative compaction and Proctor maximum densities can be used, one is never sure whether the maximum density has been allowed or not. In most cases this is not attained.

1] Emilio M. Morales holds a Master’s Degree in Civil Engineering from Carnegie Mellon University, PA., USA and is currently the Chairman Geotechnical Specialty Committee. Currently, He is the Technical Director of Philippine GEOANALYTICS, Inc. Soils and Materials Testing Laboratory and can be reached through e-mail: pgamain@pgatech.com.ph www.pgatech.com.ph

2] Spangler, M. “Soil Engineering”. 4th Ed. Harper & Row Publishers. NY, NY 1982.

3] Monohan, E. “Construction of and on Compacted Fills”. Wiley & Sons, Inc. NY, NY 1986.