Emilio M. Morales, MSCE

ABSTRACT: A large area wear slab was designed as a jointless wear slab. Originally specified with shrinkage compensating concrete (SCC). The slab was poured as an ordinary PCC concrete with temperature rebars due to non availability of SCC.

The wear slab is underlain with two layers of 300 mm thick Expanded Polystyrene EPS which turned out to be substandard.

Subsequently, approximately two months after pouring, severe cracking and dusting occurred. The cracks were predominantly spiderweblike cracks and also manifestations of shrinkage induced parallel cracking.

An investigation was requested by the Owner from the Engineer and two Third Party Engineers. This was followed by a report from the EPS supplier commissioned Engineer. The latter laid the blame almost entirely on the Prime Contractor and the Engineer.

The ensuring debate resulted in a three cornered fight between the Owner/Engineer, the Prime Contractor and the EPS Supplier.

This paper presents the Engineer’s own investigation and the final outcome of the problem.

The paper is good reading for Engineers and Contractors alike who face or are likely to face litigation due to construction problems.

INTRODUCTION

A large area Dairy Products Warehouse approximately 1.4 hectares covered area required that the wear slab on the Refrigerated Warehouse areas be of jointless construction for reasons of sanitation and hygiene.

The slab was specified to have a maximum water cement ratio of 0.42. This would result in a minimum concrete compressive strength fc’ of 35 MPa (5,000 psi).

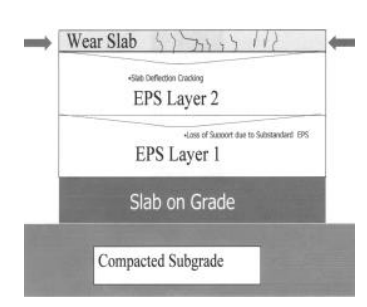

The wear slab is underlain by two layers of Expanded Polystyrene (EPS) supported in turn by a structural slab on grade. The slab on grade rests on well compacted gravel base course on compacted subgrade.

The wear slab was originally proposed to be poured using Shrinkage Compensating Concrete (SCC). However, due to non-availability, this was not possible. The Engineer then specified the use of Fly Ash in order to reduce the heat of hydration and also the water demand. However, the contractor certified to the non availability of Fly Ash at that time. As a result, the Owner ordered the pouring of the slab without SCC or Fly Ash.

The slab was required to be poured only after the roofing and cladding have been installed to protect against the weather.

Two months after pouring, the slab exhibited cracks that were predominantly spiderweb-like but also manifested parallel cracks characteristic of shrinkage cracking.

In addition, and after the warehouse was made operational, severe dusting in some areas posed a critical problem.

The dust was being recirculated by the ducted airconditioning system causing discomfort to personnel and also as a potential source of contamination to the dairy products.

As a result the Owner, in consultation with the Engineer of Record provided an overlay slab. The overlay slab sealed the old wear slab and supplanted the cracked wear slab which provided the permanent solution.

However, the Owner wanted to pin responsibility and even before the plant was placed in service, investigations have been conducted. The results of these investigations, the final conclusions and how the problem was identified and resolved are the topics of this paper.

NATURE OF CRACKS

The cracks were detected in various areas of the refrigerated stores and manifested themselves as spider web like in appearance within depressed areas. Also, parallel transverse cracks about 0.5m to 3.0m in length were detected in various areas.

The cracks only occurred in the refrigerated areas which is underlain by EPS.

INVESTIGATIONS MADE

Investigation by Engineer of Record

The Owner initially requested the Engineer to conduct an initial investigation to determine the cause/s of the cracking in the refrigerated area and to make necessary recommendations on the remedial measures needed to restore the slab to its functional serviceability.

Due to the preponderance of dishing patterns marked by spiderweblike cracks, the Engineer of Record focused on subgrade failure or settlement as the cause. However, structural calculations were also made to check that the slab would be adequate for the forklift loads imposed. This was verified to be adequate based on Westergaard analysis treating the EPS as the subgrade.

Subsequently, destructive investigations were ordered by the Engineer which consisted of:

- Concrete coring on the wear slab for Unconfined Compression Tests.

- Large diameter coring of the EPS to determine the density (and the modulus by correlation with density) and load at 10% deformation.

The results showed that:

- The concrete was grossly understrength.

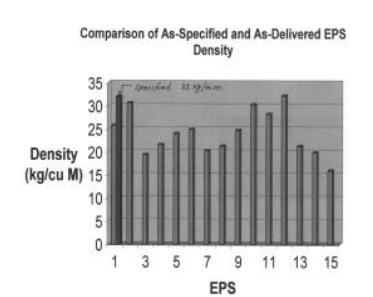

- The EPS is substandard and very much below the specified density of 32 kg/cu.m.1] and the modulus was also low.

The EPS supplier made similar and parallel tests which essentially corroborated the Engineer’s test results and clearly established that the concrete and EPS were both substandard.

Although the foregoing results initially addressed the issue, the shrinkage cracks can not be explained by these findings and additional studies were needed.

Independent Local Consultant

The Owner then also hired an independent local Consultant who concurred right with the Engineer of Record’s findings in a meeting attended by all parties.

Independent American Consultant

Not content with the foregoing, the Owners foreign Joint Venture partners hired a second independent Consultant who, after visiting the plant and seeing the cracks immediately concurred that it was subgrade failure due to the compressibility of the substandard EPS.

He stated in his report and we quote: “Based on information presented to this office to date, it is our opinion that the cracking problem was caused by failure of the Polystyrene Foam insulation to meet project specifications”.

The Owner was ready the slap claims for damages on the EPS Supplier.

EPS Suppliers Consultant

As a defensive measure, the EPS supplier recommended a Third Independent Consultant from New Zealand to prepare a report. The Owners and the Engineer agreed to this suggestion for the sake of fairness and to show good faith.

The results of this EPS Consultants findings and recommendations came as a shock to all as it overturned all the previous investigations and findings completely. This report and its conclusions needed to be discussed at length as the ensuing response to these conclusions established the actual problem and solution.

The report by the EPS Supplier’s Consultant laid the blame squarely on the Prime Contractor and the Engineer and almost dismissed the responsibility of the EPS Supplier for substandard products by a slap on the wrist.

Fortunately, this report was proven to be flowed as it made conclusions on the basis of numbers or figures which could not be supported by calculations. How this was done is the main purpose of this paper. The procedures employed by the Engineer in doing so lays the groundwork for resolution of similar problems and avoidance of litigation.

The New Zealander Consultant hired by the EPS supplier concluded that:

The cracking was mainly due to shrinkage and it identified the following as the major contributing factors to the shrinkage 2]:

⦁ “Inadequate shrinkage control measures in the floor slab design.

⦁ Excessive water in the concrete mix causing shrinkage of up to four times what would have been expected from the specified mix”

While recognizing that the “underfloor Polystyrene Supplied is below specified density” this observation was not pursued further in terms of its contribution to the slab cracking!

The EPS Consultants report totally neglected the contribution of the very low subgrade support offered by the substandard polystyrene supporting those slabs despite the crack patterns and also ignoring the conclusions of two other Independent Consultants attributing the cracking to the substandard EPS.

It also recommended an arbitrary apportionment of liability that pinned the responsibility mainly on the Designer and Main Contractor.

While the EPS Consultants report was flawed because it made general conclusions without having any basis or calculations to support these, it also proved that:

- The as laid concrete had a very high water cement ratio (W/C = 0.833)3] which is almost double the specified water cement ratio (W/C < 0.42).

- It supported the findings on the core strengths obtained.

REVIEW OF THE EPS CONSULTANTS FINDINGS

As earlier stated, the report caused some shock and alarm to the Owner and as the Engineers we were asked to comment on this report.

Our review of this report showed that:

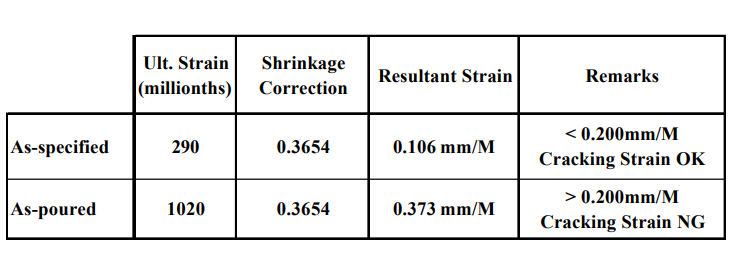

- The report was flawed because it predicted the strain on the as designed slab as 0.350mm/m (350 millionths) which later on turned out to be unsupported by any calculations!

- The report dealt with qualitative assessment that was based on generalized assumptions leading to erroneous conclusions particularly on the assignment of responsibility.

- The EPS Consultant concluded, unsupported by engineering calculations, that the concrete wear slab as designed and as-built would have cracked in the same manner. This erroneous conclusions is due to their failure to quantify by calculations the shrinkage strains which would result from the as-designed and as-poured mixes. This is due to the non recognition of th shrinkage control measures specified by the Designer which included:

- Control of W/C to 0.42

- Limiting slump to 2 inches (50mm)

- Increased strength of concrete to 5,000 psi minimum by specifying W/C to be 0.42 maximum.

- Shrinkage control rebars

- Extended curing period of 14 days by ponding

- Specified use of SCC or Fly Ash (which was not carried out with the knowledge of the Owner)

- Requirement for full enclosure before pouring of slabs.

The EPS Consultant would cursorily dismiss these measures no being “insufficient” (based on a letter dated 15 February 1997).

Herein lies the crux of the matter because we shall prove subsequently, and supported by calculations, that the measures specified were more than adequate to control cracking.

Thus, although it resulted in countless hours of engineering time and research, the study was worth it for it clearly proved that the specifications were adequate to prevent cracking despite the non use of the originally specified SCC or even in the “absence” of Fly Ash.

It also emphasizes the fact that sound Engineering can always stand on solid ground and rely on Fundamental Engineering Principles despite efforts to mask the truth.

The EPS Consultants report was proven without basis and is flawed because it can not support its shrinkage quantification of 0.350 mm/m in the light of our calculations showing that the shrinkage strains resulting from the as- specified concrete mix was well below the critical threshold strain magnitude for cracking to start (0.200mm/m or 200 millionths).

SUMMARY OF TEST RESULTS

The tests on concrete and EPS cores are included as Table “A” and Table “B” in Appendix “C”. In addition, the water cement ratio on the hardened cores as performed by BRANZ showed that the W/C Ratio is 0.833 average. These tests results already clearly established that the materials as used were substandard and grossly non complying with the specifications.

CALCULATIONS AND QUANTIFICATION OF SHRINKAGE STRAIN MAGNITUDE

The Methodology and procedures employed strictly followed the universally accepted ACI 209R-92.

The calculations showed that:

- Although the ultimate strains εsh were 290 millionths and 1020 millionths for the as-specified and as-poured concrete smaller values were obtained when various correction factors are applied as provided for in ACI 209R-92. The large disparity is in the very high Water Content of 47.9 gals/CY for WC 0.833 for the as poured concrete.

- Shrinkage correction factors were equally applied for the as- specified and as poured concrete mix. The product is 0.3654 the resulting strains are:

3. The environmental and other considerations are very important in quantifying shrinkage strains and whether such conditions would cause cracking of the slab.

4. These environmental and other factors and their contribution and effect to the shrinkage magnitude are very important and highlight the fact that shrinkage can be controlled by controlling these factors.

The calculations and references are included in this paper as an appendix as a guide to the reader.

CONCLUSION

As a result of the foregoing findings and computations, the EPS supplier’s consultant did not anymore respond nor repute the results of our studies.

The EPS supplier and the main contractor entered into a compromise agreement with the Owner and the Engineer of Record was totally cleared of any responsibility or liability.

1] Since the compressibility modulus of the EPS (Ey) can be directly correlated to the density [Horvath], the settlement of the EPS can be predicted.

2] “Floor Failure Report” Dec 1997 by New Zealander Consultant.

3] Average Value of W/C from Building Research Authority NZ (Branz)

Download Investigation of Cracking of a Large Area Wear Slab