Emilio M. Morales, MSCE

Abstract: The need for reliable, fast and inexpensive soil investigation procedures has been felt in the local construction and consulting industry. The Electric Static Cone Penetrometer (CPT/CPTU) although widely used in more developed countries has seen very limited technical and commercial applications in our country due to its near total absence in commercial testing. This paper was originally prepared as a primer for our end-user units. However, it was expanded into this paper to present the State of Practice in the gathering of soil data using the Electric Cone Penetrometer (CPT/CPTU).

The various applications and limitations of the equipment and the procedures are discussed as well as findings on the results of local correlation tests conducted in the country. Directions on future applications and enhancements are also covered to fully exploit the potential of this testing method.

1.0 INTRODUCTION

1.1 General

The Cone Penetration Test (CPT) commonly known as the Static Cone Penetration Test (as opposed to the SPT, which is a Dynamic Penetration Test) or simply the Dutch Cone Penetration test, originated in the Netherlands.

It evolved out of the need to have a relatively simple and expedient test procedure that would be more economical and cost effective when compared to the SPT and yet yield meaningful data which could be useful in site characterization and the gathering of design parameters by correlation with extensive Insitu and Laboratory Testing results.

The CPT is most useful in stratigraphic interpretation where its value is unsurpassed. Because it is a continuous test of soil resistance, it can detect minute changes in stratigraphy and consistency/density and thus give a more reliable picture of the underlying soil conditions.

Due to the wealth of data accumulated in the past throughout its evolution, soil classification is relatively well defined through correlation charts using the three basic outputs of Cone Resistance qc, Friction Sleeve Resistance fs and their ratios fs/qc known as the Friction Ratio Fr. In the case of the CPTU or Piezocone, pore pressure u is also measured leading to improvements in correlations particularly for very soft clays and borderline characterizations. Invariably, correlation with local soils are necessary, particularly for borderline correlations, but for the major generic soil types, this is fairly well established.

The Chart (after Robertson, 1991) and included as Appendix “A” is recommended for initial classification by correlations. This would normally be augmented by a limited number of Boreholes to confirm or verify the local soil characteristics specifically in Borderline correlations to come out with Detailed Stratigraphic Information on the area investigated.

Gathering of design parameters for Strength (Cu, ϕ ), compressibility (M & Dr) and other parameters have also been evolved by various researchers and for routine jobs, these correlations would suffice. For more important jobs, further tests using other established methods must be necessary such as laboratory tests and correlations with other test procedures such as the Vane Shear, Pressuremeter or Dilatometer.

1.2 History

The CPT originally started in 1932 in the Netherlands when P. Barentsen used a crude device which was made of a Gas pipe, inside of which a steel rod is inserted and to which a 60 deg. Cone was attached. This assembly was pushed down by hand, the cone resistance was read by a manometer.

Improvements to this crude device were made by Begemann resulting in a Mechanical Cone Penetrometer which added an “adhesion” jacket behind the cone tip. Using this new device, the Skin Friction could be measured by means of a manometer. Readings were made every 0.20m and the Rod string (Inner Rod and Outer Rod) is advanced alternately and incrementally while recording the manometers. A method for soil classification through the Cone Resistance and Friction Resistance became possible. In 1965 Begemann was also the first to propose that the Friction Ratio Fr could be used to classify soil layers in terms of soil type. 1]

The Electric Cone Penetrometer has eclipsed the use of the Mechanical Cone Penetrometers except for very limited applications where damage to the sensitive Electric Cone Tip is possible.

The Electric Cone Penetrometer was probably first developed in Germany during the war.

It was soon recognized that this was a very important development which eliminated the uncertainties and inaccuracies associated with the Mechanical Cone Penetrometer. Among its advantages relative to the Mechanical Cone Penetrometer are:

- Elimination of erroneous interpretation of test results due to Friction between inner and outer rods.

- A continuous testing with a continuous rate of penetration without the need for alternative movements of different parts of the penetrometer tip and no possibility for undesirable soil movements influencing cone resistance.

- The simpler and more reliable electrical measurements of cone resistance with the possibility for continuous readings and easy recording of results.

Further improvements were made such as the incorporation of an inclinometer and introduction of a pore pressure (u) measuring system resulting in the CPTU or the Piezocone.

1.3 Details of the CPT

The Cone Penetration Test (CPT) is an In-situ procedure whereby a cone of Fixed Dimensions is pushed into the ground at a constant rate of 20mm/sec + 10%. The Penetrometer Tip as used in the Modern Day Electric Cone Penetrometer consist basically of four (4) major parts. The Cone, the Sleeve, the Inclinometer and the Body.

The cone has a 60 deg. Apex with a maximum diameter of 35.7mm with a height of 30.9mm and a shoulder height of 10mm. The maximum cross sectional area of the Tip Base is 1,000 mm2 corresponding to a diameter of 35.7mm and a height of the conical part of 30.9mm.

The Friction Sleeve has an outer cylindrical surface area of 15,000 mm2 + 2% which corresponds to a sleeve length of 133.7mm and is located above the tip.

The inclinometer detects and registers the inclination of the penetrometer from the vertical which is critical to prevent damage to the sensitive parts of the penetrometer or the drill string.

The body holds the three together and contains the Electrical Strain Gages to monitor the Tip and Friction Resistances and also the inclination reading in the form of electrical signals which are transmitted via connecting cable to an analog to digital converter which records the Friction and Tip Resistance and inclination versus depth and sends them to the computer. The computer then processes these data into usable output after interpretation of the signals using the prestored Penetrometer and Inclinometer Calibration Data.

The Cone is connected to a string of Push Rod which is inserted downward at a constant rate of Penetration of 20mm/sec by a thrust machine with a push capacity of at least 5 MT to 20 MT. Depth of Penetration is automatically recorded by a Linear Transducer synchronized with the other analog signals fed into the converter.

Normally, a Friction reducer is located above the penetrometer not less than 1,000mm from it. Schematically, the set up is shown below in Fig. 1.0:

1.4 Present State of Technology

Due to its reliability and popularity, the Electric Cone had undergone numerous improvements in accuracy and performance.

In addition, and due to advances in Electronics and Computer Technology, new capabilities are being added which would make possible the gathering of other parameters needed in Geotechnical Engineering and Geoenvironmental applications.

The development of more accurate and reliable strain gages has allowed the gathering of more reliable data. Multi channel capabilities, electronics miniaturization and improvements in signal processing and conversion have allowed gathering of various data concurrently or separately such as:

- Cone Resistance (qc)

- Friction Resistance (fs)

- Inclination ()

- Pore Pressure (u)

- Seismic Wave Information

- Shear Modulus G

- Ground Water Chemical Properties

- PH

- Resistivity

- Conductivity

- Heat Flow (T)

- Density (s), Moisture Content (MC) by Nuclear Probe

The Basic Electric Cone Penetrometer as we know it today, as a result of these advances, has come to be known as a rugged, reliable and relatively cost effective In-situ testing device for Geotechnical Engineering.

1.5 Test Standardization

During its early stages of Development, various sizes and configurations from various countries were in use. In order to provide reliable data through correlations, it was recognized that standardization was highly necessary as differing Penetrometer Geometry and the test procedures could produce highly differing test results. Since to some extent, soil strength is dependent on the rate of deformation (insertion of penetrometer) it was necessary to standardize this to 20mm/sec + 10%.

Several National Standards such as the Swedish Standard for Cone Testing and the US ASTM D-3441-86 have evolved.

In a bid to unify various national standards, the ISSMFE (International Society for Soil Mechanics and Foundation Engineering) came out with a reference Test Procedure which is expected to be adopted as The world standard for Cone Penetration testing. This is expected to be revised soon.

The present Swedish Standard for Cone Testing of 1993 exclusively refers only to the Electric Cone Penetrometer by specifying that measurements shall be done by Electrical means.

The mechanical cone is used less and less today because of related inacurracies and the cumbersome test procedure involved.

2.0 OFFICE & FIELD PROCEDURES

2.1 Equipment

Essentially, the Electric Cone Penetrometer set up would include the following:

- Thrust Machine 20 MT Push Capacity (normally a special purpose Built Truck)

- CPT Set

- Cone

- Friction Reducer

- Push Rod String

- Cable

- Field Computer & Data Logger

- Field Tools for Clearing and Maintenance of CPT

- Office Computer

This is shown schematically in Fig. 1.0.

2.2 Office Procedure

2.2.1 Job Diskette Preparation

In order to avoid confusion in the Field, as invariably CPT Exploration would involve numerous exploration points per project and because the system is fully automated, it is necessary to prepare the exploration plan in the office.

Normally, Job Floppy diskettes would be prepared in the office which would contain the following information:

- Job Number

- Project Name

- Location

- Client Name

- Cone & Inclinometer Calibration Data

2.2.2 Calibration

In addition, regular calibration at maximum 3 month intervals are carried out in the office as mandated by ISSMFE. The calibration is done to ensure that the cone & sleeve strain gages are within tolerance using a Force Transducer that is in turn calibrated to a higher standard.

2.2.3 De Airing of the CPTU

In addition to the foregoing and in the case of the CPTU (Piezocone), the Pore Pressure Filter System needs to be thoroughly deaired in order to ensure proper response of the Pore Pressure system to minute changes in Pore Pressure during the Pore pressure Dissipation test. This is done by subjecting the Filter to immersion in glycol inside a closed chamber. Vacuum is introduced to allow the air bubbles to boil out of the Filter and the Glycol solution. The Filter is shipped to the field completely immersed in Glycol using say a plastic or rubber sheath until it is inserted into the soil.

2.3 Field Procedure

2.3.1 Field Test Operations

In the field after equipment set up, the Job Diskette is loaded and the corresponding test point location is chosen.

The test is initialized by first ensuring zero (No Load) reading on the Penetrometer for qc and fs by hanging the CPT Cone in the Drill String on air. This is recorded antomatically by the software as a correction.

Normally a hole is predrilled by Auger on the Thin Dessicated Dry Crust to prevent damage to the CPT Tip before starting penetration

The verticality of the Push Rod and Thrust machine is checked in order to ensure that the thrust is vertically aligned. The deviation should not exceed 2% and the axis of the rods should coincide with the thrust direction. Normally levelling is done by Hydraulic Jacks.

The rate of penetration shall be 20mm/sec + 10% and stops are only made for Push Rod addition or when performing Pore pressure Dissipation Tests.

Readings are taken by the instrumentation and software for qc & fs at maximum 50mm (2 inches)

increments averaged to within 50mm.

Depth of penetration is also recorded and measured with an accuracy of 100mm by an automatic linear transducer (Depth Gage) with a resolution of 10mm.

Most software have real Time Screen Displays of qc, fs, Fr, Inclination θ , Pore Pressure (u) and Rate of Penetration to enable the operator to control the operation and monitor critical parameters and ensure that tests are performed properly.

The results are automatically stored in the hard disk of the Field Computer and the Job Floppy Diskette after the test.

2.3.2 Maintenance and Repair

In between tests, the penetrometer is visually inspected for any damage. All the seals are also inspected and any dirt inclusions are removed or cleaned to ensure proper performance during the test. If necessary, the penetrometer can be field disassembled to replace any broken seals or O-Rings and to lubricate the O-Rings.

2.4 Office Data Reduction

The data gathered in the field contained in the Job Floppy Diskette is sent to the office and is reduced and interpreted to yield the stratigraphy of the site investigated and other data which could be used for determination of Design Parameters.

Software is also available to automatically determine soil parameters but this has to be tempered with local experience.

3.0 TEST DATA GATHERING AND PRESENTATION OF RESULTS

3.1 General

The primary purpose of the CPT is to gather soil resistance data in order to effectively characterize the soil continuously with very little gaps in the stratigraphy. Through well established correlations and augmented by local experience, the site characterization is accomplished most efficiently. In stratigraphic characterization, the electric CPT is acknowledged to be the best insitu tool because it gives a continuous resistance profile of the subsurface. Because it is relatively inexpensive to perform, numerous points could be investigated to yield a more accurate horizontal characterization of the site.

Although various parameters obtained by correlation do not replace more accurate laboratory tests, the quality of data can be upgraded by local correlation. This is done by performing a limited number of boreholes and performing laboratory classification and strength tests (shear strength and compressibility) on the samples retrieved.

Essentially, stratigraphic characterization and parameters correlation (Strength, Compressibility, Dr, Gs, etc.) are obtained by the CPT through the continuous recording of the following data:

qc – Cone Resistance

fs – Sleeve Resistance

Fr – Friction Ratio = fs/qc

μ – Pore Pressure (for the Piezocone)

Because the CPT is standardized (As, Ap and rate of penetration) the correlation with numerous other tests performed in the past worldwide have given a wealth of data to make such correlations reliable.

These cone data are discussed individually: 2⎦

3.2 Cone Resistance (qc)

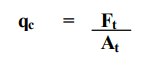

The cone resistance is the force per unit area which is obtained by the dividing the total axial force against the tip by the cross sectional area of the Tip Base (1,000 mm2).

Thus:

Alternatively:

In the special case where u = 0 or u is negligible, qc≈qt. The cone resistance is expressed in Mpa or Kpa.

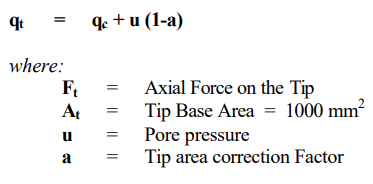

3.3 Local Side or Sleeve Friction (fs)

The local side Friction is obtained by dividing the total Friction force acting axially on the Friction Sleeve by the outer surface area of the sleeve.

In the special case where the pore pressure effects are zero or negligible, fs ≈ ft. The local sleeve friction is expressed in Mpa or Kpa.

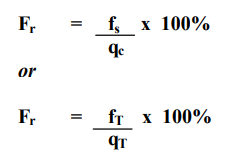

3.4 Friction Ration (Fr)

The Friction Ratio is the ratio between the local sleeve friction (fs) and the cone resistance (qc).

The ratio is expressed as a percentage. Normally, Fr for sands is seldom over 1% and for clays is normally > 4%.

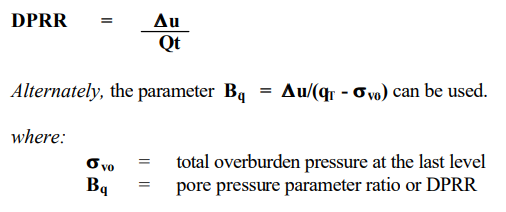

3.5 Pore Pressure u and Change in Pressure (Δ u)

With the advent of the CPTU or Piezocone, which measures pore pressure and enable the performance of Pore Pressure Dissipation Tests, more detailed tests can be performed and strength parameters for very soft soils can be obtained.

The Differential Pore Pressure ratio DPRR is the ratio between the generated pore pressure and the cone resistance at the actual level.

Recent studies have shown that even with careful procedures and corrections for pore pressure effects, the measurement of sleeve friction (fs) is often less accurate than the cone resistance.

To overcome problems associated with sleeve friction measurements, several classification charts have been proposed based on qT and pore pressures (Janbu and Senesset). The chart by Janbu & Senesset use the pore pressure parameter Bq.

Experience has shown that, although the sleeve friction measurements are not as accurate as qT and u, generally more reliable soil classifications can be made using all three pieces of data (qT , fs & u). Thus, the normal correlation charts for characterization is three dimensional. 1]

3.6 Pore Pressure Dissipation Tests 3⎦

The CPTU or Piezocone has the potential of providing estimates of the in-situ coefficient of consolidation from dissipation tests. A dissipation test can be performed at any depth by interrupting the penetration at that depth. This will be discussed in later sections.

4.0 INTERPRETATION OF CPT/CPTU DATA

4.1 General

Numerous studies and data correlation have been made in the past as the CPT/CPTU evolved from a simple penetration test to what it is today. With the advent of sophisticated electronics and test standardization, correlation with various soil parameters could be made with increasing confidence. However, as in all applications in soil mechanics, such correlations need to be tempered with local experience and local soil behavior and validated by actual Laboratory Tests until the local correlations are adequately established as to be reliable. Various soil information can be gleaned from the simple CPT Tests and when augmented with pore pressure data from the CPTU, increased accuracies and reliability can be obtained.

The following correlations and soil information may be obtained with the CPT/CPTU tests:

4.2 Stratigraphy

The CPT found its most useful and valuable application in stratigraphy and site characterization. And in this aspect, this insitu test is most superior to any existing method because it provides a continuous profile of the soil and is relatively inexpensive. Thus, more numerous test locations can be done providing a closer interval for visualization of soil conditions. For routine jobs the CPT test would suffice and for more critical jobs of large magnitude, the CPT can be augmented with a limited number of Boreholes and Laboratory Tests.

The stratigraphic characterization is obtained using the Basic CPT Data qc, fs, Fr and u.

The characterization is best done using the Three Dimensional correlation chart by Robertson (1990) and included in Appendix “A”.

Using raw CPT Data or normalized data, one can determine characteristic soil descriptions of soils using this chart. Only occassionally, when borderline cases are encountered in routine jobs, is there a need to do more detailed sampling by borings.

Robertson suggested that the charts are still global in nature and should be used as a guide to define soil behavior type based on CPT and CPTU data. Factors such as change in stress history, in situ stresses, densitivity, stiffness, macrofabric, mineralogy and void ratio will also influence classification.1]

Essentially for clays and silts, Cone Penetrometer is undrained thus measurement of Pore Pressure is important since the rate of PP Dissipation is a key to classification. Cone resistance should be corrected for pore pressure effects. In addition, measured pore pressures can also be used directly for interpretation in terms of soil design parameters.

4.3 Soil Unit Weight & Relative Density Dr

4.3.1 Soil Unit Weight (s)

Larsson and Mulabdic (1991) based on tests performed in Sweden and Norway, proposed the chart in Appendix “B” for obtaining a rough estimate of soil density for clays. This is an iterative procedure since an initial estimate of γ s is necessary to compute net cone resistance and Bq.

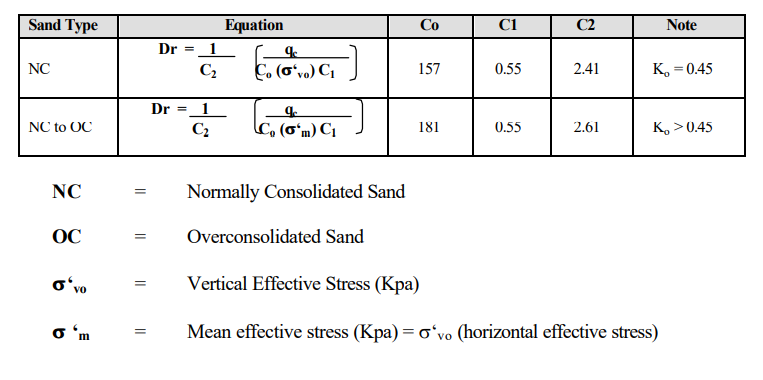

4.3.2 Relative Density Dr

Several relationships have been evolved for determining Relative Density (Dr) of Sands. However, ageing effects tend to increase cone resistance and no interpretation procedure could take account of ageing. Thus, to some extent, the obtained Dr should be referred to us “equivalent” Dr as recommended by Robertson. 1]

The value of Dr can be obtained from the chart in Appendix “D” or in equation form based on the values below:

4.4 Strength Characteristics

Various procedures have been evolved from which direct correlations can be obtained to yield soil strength parameters out of basic CPT data (qc, fs & u).

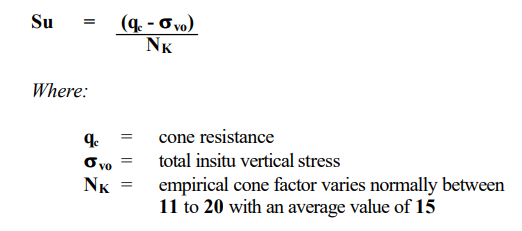

4.4.1 Clay & Fine Grained Soils

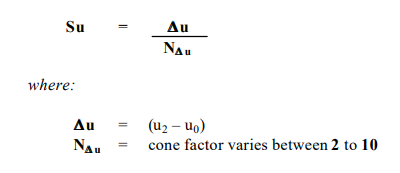

The undrained shear strength (Su) can be determined in several ways from empirical correlations.

The empirical correlation is of the general form

Robertson recommends the following procedures for Su determination: 1]

1) For deposits where little experience is available, estimate Su using the total cone resistance (qt) and preliminary cone factor values (Nkt) from 15 to 20. For a more conservative estimate select the upper limit.

For normally and lightly overconsolidated clays, Nkt can be as low as 10 and for stiff fissured clays as high as 30.

In very soft clays, where there may be uncertainties in the accuracy in qt estimate Su from the excess pore pressure (Δ u2) using NΔ u from 7 to 10 in the CPTU.

2) If previous experience is available in the same deposits, the value suggested above should be adjusted to reflect this experience.

3) For larger projects, where high quality field and laboratory data may be available, site specific correlations should be developed based on appropriate and reliable values of Su.

4.4.2 Coarse Grained Soils

Cone penetration in coarse grained soils is generally undrained, thus, no excess pore pressures are generated. Established correlations using large laboratory calibration chamber tests have been made with this assumption.

The procedure as recommended uses the charts in Appendix “E”.

The ϕ ′ from relatively uniform uncemented clean sand is empirically estimated from Fig. 5.56 in Appendix “E”. Figure 5.55 can be used to adjust the estimated ϕ ′ to account for variations in compressibility and Ko. A reasonably conservative value of ϕ ′ should be selected based on the range obtained.

4.4.3 Intermediate Soils (Clayey Sands to Silts)

The methods for interpretation applied for clays or sands may not be totally valid for silts as penetration in this material is partially drained. In this regard clay content of the silts is important.

It is important therefore to determine the type of drainage conditions encountered during the tests. If the design problem involves undrained loading and the CPT is undrained, then the CPT data can be interpreted in a manner similar to clay and similarly for drained loading and drained CPT in sands.

4.5 Compressibility & Consolidation Characteristics

4.5.1 Coefficient of Permeability (k)

The CPTU Pore Pressure Dissipation tests could give the plot of pore pressure decay over the time the test was performed. From this data, τ 50 – the time for 50% dissipation can be obtained.

Robertson proposed a chart relating τ 50 (minutes) to Kh (cm/sec) since drainage in the CPTU is essentially horizontal.

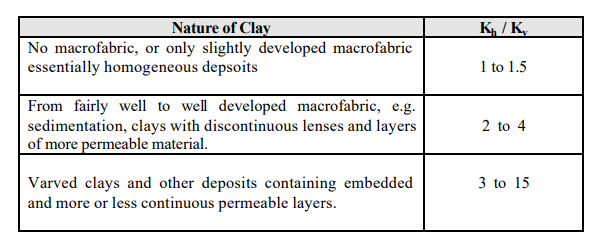

Vertical Permeability Kv can be obtained from well established field values relating Kv to Kh

after Jamiolkowski 1985 and presented in chart form below:

4.5.2 Coefficient of Consolidation (Ch)

The coefficient of consolidation Ch in the horizontal direction can be approximated from the chart as proposed by Robertson (1992) from an extension of the work by Houlsby & Teh and shown in Appendix “F” relating τ 50 as defined above and Ch (cm/sec2).

The relationship between Ch and Cv – the coefficient of consolidation in the vertical direction is obtained similarly from the above table relating Kh to Kv.

5.0 DIRECT APPLICATIONS OF CPT/CPTU DATA

In the foregoing section, interpretation of CPT/CPTU Data was directed towards correlation with soil strength parameters aside from other properties such as unit weight, relative density, stratigraphy, etc. These parameters in turn can be plugged into the various formulas (Theoretical or Empirical) to yield Bearing Capacity, Settlement, etc.

However, and particularly for Driven Piles, direct applications of CPT/CPTU Data could result in direct prediction of Pile capacity. The CPT procedure is a scale model of a Pile being inserted into the ground. Thus predictions of capaity are fairly more reliable. The reason being the ability to do continuous profiling of the subsurface soil response.

Superiority of the CPT method over non-CPT methods have been confirmed in other studies. 1]

Literature is replete procedures to use data gathered from the Electric CPT/CPTU Tests directly to provide solutions such as:

- Pile Capacity and Settlement

- Bearing Capacity of Shallow Foundations

- Settlement of Shallow Foundations

- Ground Improvement Quality Control

- Liquefaction Assessment

In all the foregoing, reduction factors need to be applied to CPT Values. The need for such reduction factors is due to scale effects of the test, rate of loading or insertion technique. 1]

6.0 CONCLUSION AND SUMMARY

The foregoing presents the Electric CPT/CPTU its advantages and advantages in obtaining soil parameters needed in Geotechnical Engineering and Foundation Design.

Its ease of use resulting in reduction in cost of investigation without degradation of information obtained from such tests is certainly an important consideration.

It is hoped that this paper would pave the way for increased understanding and wide acceptance of the procedure as an invaluable tool in Soil Exploration.

ABOUT THE AUTHOR

Engr. Emil M. Morales Graduated from Mapua Institute of Technology where he earned his Bachelor of Science Degree in Civil Engineering. He Finished his Master of Science Degree in the same field at Carnegie Institute of Technology, Carnegie Mellon University, Pittsburgh, PA, USA.

He worked as a Project Engineer at D’Appolonia Consulting Engineers, Monroeville, PA. Where he was involved in the preparation of Software for Data Reduction for the Menard Pressuremeter.

He attended a short course in the Use of the CPT, Pressuremeter and the Dilatometer at Texas A&M University under Dr. Briaud.

He also recently trained in CPT Operations, calibration, maintenance and Software at the facilities of A. P. Van den Berg in Heerenveen, the Netherlands.

He is currently Chairman of the ASEP Geotechnical Committee and a Life Member of the same Association. He is also a member of the ASFE – Professional Firms Practicing in The Geosciences, ASCE, ACI, CRSI & ASTM.

1] Lynne and Robertson. “Cone Penetration Testing” 1st Ed., 1997. Blackie Academic Press, London, UK

2] Swedish Geotechnical Institute. “Recommended Standard for Cone Penetration Test”. Linkoping & Swedish 1992, Swedish Geotechnical Institute.

3] Briaud, J.L. “The Cone Penetrometer Test.” 1991 FHWA Office of Technology Administration, Virginia, USA

Download The Electric Cone Penetrometer and Its Use in Geotechnical Engineering Services