Emilio M. Morales MSCE, F.PICE. F.ASCE, F.ASEP 1]

ABSTRACT: Quench Tempered (QT) or Thermo Mechanically Treated (TMT) rebars have crept into the market replacing the Micro alloyed (MA) steel rebars almost completely without the knowledge of the Design Engineering Community as well as the end users.

The proponents of QT/TMT rebars have stated that since these rebars have comparable Physical Test Performance when subjected to Static Tension and bend tests, then it could be a viable and safe replacement to MA rebars without qualification. Herein is where the danger lies, because QT/TMT rebars behave quite differently under Cyclic loading and are also very much affected by heating, welding, bending, galvanizing and threading procedures employed in their use particularly in high rise buildings under Seismic Zone 4.

Advanced countries have warned against these dangers and we believe it is our duty to inform the public and the Profession of the dangers associated with their use in Seismic Zone 4.

In a recent ASEP dialogue with the representatives of the Rebar manufacturing sector conducted together with representatives of the Bureau of Research and Standards, claims have been made that the rebars can be welded and used in high rise buildings under Seismic Zone 4 Conditions. This claim is very far from the truth and at best could only be done so under very strict qualifications. We have asked the Industry representatives to submit proof to prove their claims. This was received 18 March 2010 but still do not offer any satisfactory explanation as to performance under cyclic loading in a severe earthquake environment.

The premature and relatively localized and very limited yield zones of QT/TMT rebars under repeated Cyclic Loadings would result in spalling of the concrete cover in Reinforced Concrete columns and failure of the affected rebars by premature buckling and eventual tension failure of the rebars.

Various studies and research in Italy 2], New Zealand and elsewhere have pointed to the Dangers posed by these rebars when used in Seismic Zone 4.

This paper is aimed at alerting the Engineering Community to the uninformed use of QT/TMT rebars in order to reduce the dangers posed by such usage.

1 INTRODUCTION

The Structural engineering practitioners are faced with problems involving material selection. But nowhere has this been more acute than in the use of reinforcing bars that do not meet design demands in Seismic Zone 4 particularly as it applies to cyclic loading under seismic excitation.

The problems particularly are related to the use of Quench Tempered (QT) or Thermomechanically Treated (TMT) Rebars and accentuated by the noticeable artificial absence of the commonly used and previously available Microalloy (MA) rebars. Thus, the engineering community is deprived of a safe choice and left with a rebar that strongly affects the structural performance and adequacy of our designs in a retrogressive way under cyclic loading.

But first let us try to define each of these processed steel types:

1.1 Quench Tempered (QT) Rebars

The QT or TMT bar is manufactured by rapid cooling of plain low Carbon steel by a fine water spray. The quenched surface is tempered by the heat of the red hot core. This results in a layered steel rebar section with a heat treated outer skin (high tensile strength of tempered martensite and a ferrite/pearlite core with slow cooling inner core. The end result is a steel bar with a higher composite yield and tensile strength than the parent material to start with.

1.2 Microalloyed (MA) Steel Rebars

The micro-alloyed steel derives its strength from alloying materials specifically vanadium and Carbon and consists of a uniform material cross section manufactured from steel billets. The alloys are added in the heat. This is the commonly used Rebar until it suddenly disappeared in the marketplace.

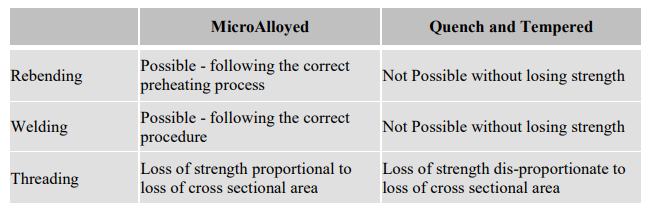

1.3 Comparison of QT/TMT Rebars vs. Microalloyed (MA) Rebars3]

Major research in highly advanced countries have pointed the problems associated with QT/TMT Rebars. This is clearly indicated in the publication by Bothara. 3]

1.3.1 Why have MA Rebars Disappeared in the Market?

Microalloyed rebars began disappearing in the market when most major local manufacturers completely shifted to QT/TMT rebars. In the dialogue with steel Industry representatives and ASEP with BRS, the representatives claimed that Microalloyed (MA) rebars are more expensive to produce because the alloys were expensive. Thus, in the blink of an eye, the public and the engineering design profession were deprived of a “healthy” choice that will not cause endangerment to structures.

1.3.2 Why the Endangerment?

There is a clear and present danger in the use of QT/TMT rebars in Seismic Zone 4 due to the non-ductile behavior of QT/TMT rebars under conditions that are typical or common in local Construction practice.

In addition, there are critical considerations that may be difficult for QT/TMT to meet under various conditions that it will be exposed to, such as Fire exposures and retempering due to inappropriate welding, contrary to the very strict procedures imposed on the welding of QT/TMT rebars, as well as critical outer skin loss when these are threaded for mechanical couplers4.

In addition, Performance in highly critical cyclic Seismic Loading is put to question.

The premature and relatively localized and very limited yield zones of QT/TMT rebar under repeated Cyclic Loadings would result in spalling of the concrete cover in Reinforced Concrete columns and failure of the affected rebars by premature buckling.5] Various studies and research in Italy, New Zealand and elsewhere have pointed to the Dangers posed by these rebars when used in Seismic Zone 4.

This paper is aimed at alerting the Engineering Community to the uninformed use of QT/TMT rebars in order to reduce the dangers posed by such usage.

The author seeks to highlight these problems in order for the engineering community to realize the dangers associated with the use of QT/TMT rebars so that these could be better understood.

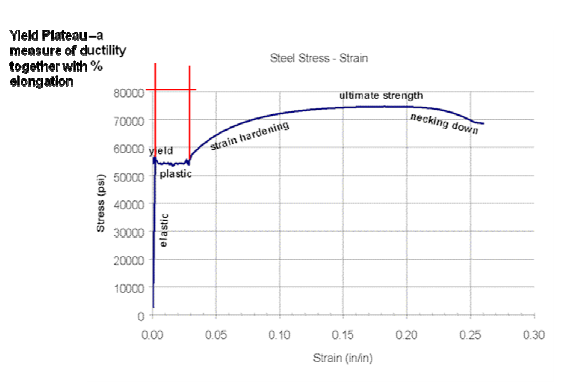

2 STATIC STRESS STRAIN DIAGRAM

The static Stress vs Strain diagram of common steels is depicted in the Diagram below. The important thing to consider here is the size of the Yield Plateau or the Ductility of the Steel which is a function of both the TS/YS ratio as well as the % Elongation.

As can be seen from the Diagram at the right, the Yield Plateau initiates upon yielding and propagates almost horizontally. This indicates that straining occurs even without a proportional increase in stress until Strain Hardening sets in and a significant stress increase occurs before reaching the ultimate tensile failure condition which is the peak of the curve. A rapid decay in the stress occurs with decreasing steel cross sectional area due to necking.

A very important consideration is the length of the Yield Plateau represented by the TS/YS Ratio and the % Elongation. PNS 49 requires a minimum TS /YS Ratio of 1.25 as most other International Codes in high Seismic Risk areas. In addition minimum elongation values required are 12 % to 16 % for Weldable Steel. In addition, a cap of 540 MPa is placed on the yield Strength of Weldable steel bar for Grade 415 W Steel.

Why is there a cap on the Yield Stress?

There is a cap of 540 MPa on the yield stress for Grade 415 steel rebar in order to ensure that yielding will occur on the steel first before the concrete. Otherwise, concrete failure which is an explosive type of failure will occur contrary to the expectations of the designer.

3 WHAT INTERNATIONAL CODES SAY

NZ Standard 3101:2006 Concrete Structures Part 1 Section 5.3.2.2

“Restrictions on in-line quenched and tempered process shall not be used where welding, hot bending, or threading of bars occurs.”

“It is important to note that any process involving heat e.g. Welding, galvanizing and hot bending adversely affect the mechanical properties of quench and tempered reinforcing bars by modification of the microstructure.

NZ Standard 3101:2006 Concrete Structures Part 2

Section C-5.8.2 In Line quenched and tempered steel bars

Welding of in-line quenched and tempered bars can have detrimental effects on the strength and ductility of the bars and associated connection. AS 3600 requires designers to assume that the strength of such reinforcement has a design strength of 250 MPa when raised to the temperature associated with welding, galvanizing or hot bending. Such a requirement is considered inappropriate in a seismically active country where concentration of yielding at a weld position would be undesirable and could result in brittle failure. (Empasis by author)

4 THE PROBLEMS ASSOCIATED WITH QT/TMT BARS

4.1 Local Studies Presented by PISI 6]

In a written communication by the PISI dated February 10, 2010 7] addressed to ASEP, a report by MIRDC 8] was attached and furnished to ASEP in response to the ASEP request during the dialogue.

In the attached report, it was concluded that the QT/TMT rebar’s TS/YS ratio “is attainable” (NOT Categorically COMPLYING) as results indicate that the rebars tested are marginally lower than the minimum 1.25 Ratio required in most instances.

The abstract8] summarizes the study and which we quote verbatim as follows:

“Characterization of Locally manufactured Tempcore Steel reinforcing steel bars (rebars) produced by the QST process was undertaken to ascertain its mechanical properties in relation to established standards as well as meet requirements of structural Engineers. Different sizes of Tempcore rebars gathered from two local manufacturers were subjected to chemical analysis, tensile testing and metallography on the as- received, heat treated and welded basis. Locally produced Tempcore rebars can be manufactured to meet established domestic standards particularly on meeting a tensile to yield (TS/YS) ratio of ≥ 1.25. Yielding characteristics as required by structural engineers can be satisfied by Tempcore Rebars. Heating at temperatures up to 500 degrees C does not affect mechanical properties, although increasing this Temperature to 700 Deg C reduces the Yield and tensile Strength. Although CE values may indicate weldability, inconsistent properties may be obtained for smaller sizes of rebars. The use of AWS E 10018 produces better properties on welding of Tempcore rebars than using the more commonly available AWS 7018 Electrodes. Stress relieving after welding improves mechanical characteristics of Tempcore rebars.” (Underlining by author)

The test results and studies made on static tensile tests and do not include cyclic loading conditions.

4.2 Welding Associated Problems

“Welding of any kind to QT steel will reduce its strength and must not be attempted. The welding temperatures far exceed 700oC in most common instances leading to distempering of the rebars.

Welding of QT Grade 500E steel should not be allowed under any circumstances. This includes welding of bars to achieve electrical continuity. For such applications, it is unlikely that Grade 500E steel will be required and other more weldable steels should be chosen.4]

In summary, designers should not rely on welding of Grade 500E steel and fabricators/contractors should not allow welding of this material.9”

Welding a Quench and Tempered (QT) reinforcing bar raises the steel above the temperature it was tempered at and without the controlled quench and temper process it will cool slowly back to ambient temperature. Through this cycle it will lose the strength of its external case and revert back to steel with much lower yield strength. Micro-Alloy (MA) weldable reinforcing steel can be welded such that it maintains its ductility and its strength using ordinary E70XX Electrodes.

CONCLUSIONS IN NEW ZEALAND STUDY 9]

- Q&ST Grade 500 reinforcing can not be welded without strength loss. It is recommended that a suitable warning be added to the Standard to this effect. This is covered in the amendment to NZS 3101(7)

- The standard implies that lap welds are possible with Grade 500E but testing suggests that lap welding to the Standard specified requirements does not provide a sufficient margin against failure of the weld before failure of the bar(2). This is addressed in NZS 3101, however, it is recommended that appropriate amendments also be made to AS/NZS 1554.3 to warn specifiers/designers/constructors of the likely performance of this detail

- The Standard implies that butt-welding of Grade 500 E reinforcing steel is possible but is silent on the performance expected. Discussion at the recent seminars on Grade 500E reinforcing steel indicated that currently there may not be a suitable welding electrode available to provide confidence that failure will always occur in the steel rather than the weld when the bars are at the higher end of the maximum tensile strength range allowable in AS/NZS 4671 and the bars containing the weld are required to yield at over strength. Although this issue is covered in the amendment to NZS 3101, it is essential that it is also addressed in AS/NZS 1554.3 as butt-welds complying with the Tables in this Standard are deemed to be pre-qualified and could be assumed to be capable of developing the strength of the bar, unless warnings are given to the contrary.

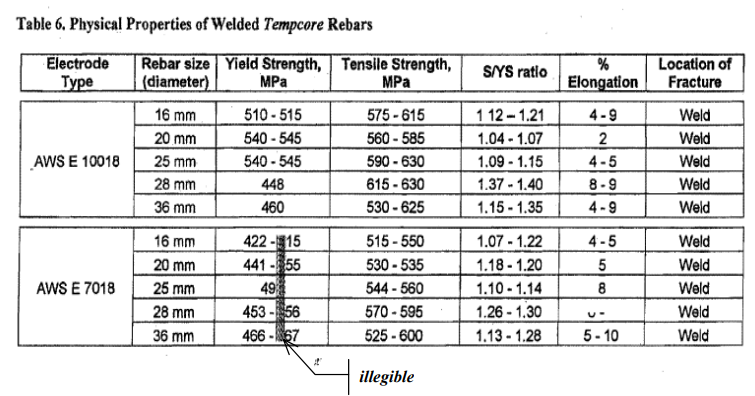

4.3 Results of the MIRDC Study

The results of the MIRDC study by Dr. Fudolig10] kindly furnished by PISI for ASEP Consideration indicates results that clearly show the mechanical performance of welded QT/TMT rebars using two Electrode types on different rebar Diameters.

Table 6 above from the MIRDC study11] shows the reduction in the Tensile strength and yield strengths and corresponding TS/YS ratio for welded joints for both AWS 10018 and AWS E 7018 Electrodes Types. What is more critical is the observable marked reduction in % Elongation for most of the rebars whether welded with the more expensive E 10018 Electrodes or the Standard E 7018 Electrodes.

The % Elongation results for the welded joints would not meet the requirements of PNS 49 2002 12for Grade 415 W Weldable Steel, which require a minimum range of 12 % to 16 % Elongation under a Static Tension test. A lack of elongation limits the straining region resulting in premature spalling and failure of the concrete cover in turn leading to premature buckling and eventual tensile failure.

4.4 But where is the Economy?

The savings obviously accrue only to the manufacturers as the cost of producing QT / TMT rebars is very much less than MA rebars.

However, this does not translate to savings to the end user as the cost of welding and the required welder skills are much more stringent than ordinary MA rebars if the correct procedures are followed, even then it does not guarantee adequate performance.

We again cite a passage in the Report by Dr. Fudolig (Ref 9) as follows:

“The choice of AWS E10018 is based on D1.1-94. The use of this kind of electrodes is also recommended for Tempcore rebars. It must be noted that AWS E 10018 electrodes are not readily available in the Philippines. The more commonly used electrode for welding of rebars, particularly for conventional type of rebars, is AWS 3 7018, which are also locally produced. Furthermore, cost of ASW E 10018 in the local market is seven (7) times that of AWS E 7018.”

So where is the economy? Even if the Tempcore bars could be allowed for use, the necessary technical welding skills as well as the special electrodes required (which do not even guarantee satisfactory performance) for QT / TMT rebars would provide an insurmountable barrier for its safe usage in general construction in Seismic Zone 4.

4.5 Tack Welding

“Tack welds can be seen as almost insignificant to the site operative. They simply help to add stability to a cage, or facilitate placement. However, placement of weld material on Grade 500E steel (Microalloyed or QT) may well lead to premature failure of the rebar. The tests at Auckland University support this. Reported failures of bars include those due to application of welding and due to inadvertent damage from gas cutting equipment.3]

The Department strongly recommends against any tack welding of Grade 500E steel, and urges vigilance by designers, fabricators, contractors and inspectors to avoid damage that could jeopardize the safety of the structure.” 3]

“Q&ST Grade 500 reinforcing cannot be welded without strength loss. It is recommended that a suitable warning be added to the Standard to this effect. This is covered in the amendment to NZS 3101. 4]´”

4.6 Bending problems

Bending of Grade 500 MPa rebars will require that it must be heated if it is to be straightened or re-bent. Straighthening the steel cold will result in work hardened areas reducing the bars ductility just where it needs it when an earthquake happens. To re-bend Grade 500 the steel must be heated 700-800 degrees Celsius which is above the temperature at which QT reinforcing cannot be heated without losing its strength. It is important to note re-bending steel is a specialist process and must be carried out to steel manufacturer’s specifications.

The melting Temperature of steel is over 1500 degrees Celsius well beyond the temperature at which QT starts to lose its strength. Welding of course involves heating steel up to and beyond its melting Temperature and so welding is an obvious problem for QT steel if full strength is to be maintained. 3]

It is important that a QT bar is not heated above its tempering temperature. If it is, the outer strong casing will be tempered and revert to the same properties as the internal core and the bar will be significantly weakened. The temperature that this change starts to occur is as low as 450 degrees Celsius. An MA rebar on the other hand will not change if heated to the same temperature.

The common processes that occur above tempering temperature are hot bending and of course welding.

C8.5.2 NZ Standards:

“Welding of in-line quenched and tempered bars can have detrimental effects on the strength and ductility of the bars and associated connection. AS 3600 requires designers to assume that the strength of such reinforcement has design strength of 250 MPa when raised to the temperatures associated with welding, galvanizing or hot bending. Such a requirement is considered inappropriate in a seismically active country where concentration of yielding at a weld position would be undesirable and could result in brittle failure.

4.7 Heating High-strength and Heat-treated Steels

The effect of elevated temperatures on high strength and heat-treated steels should be thoroughly investigated. For example, quenched and tempered materials will undergo radical changes in their mechanical properties as well as toughness when subjected to temperatures above 260 degrees C (500 degrees F).

Grade 500 MPa reinforcing steel must be heated if it is to be straightened or re-bent. Straightening the steel cold will result in work hardened areas reducing the bars ductility just where it needs it when an earthquake happens. To re-bend Grade 500 the steel must be heated to 700 – 800 degrees Celsius which is above the temperature at which QT reinforcing cannot be heated without it losing strength. It is important to note re-bending steel is a specialist process and must be carried out to the steel manufacturers specifications.

4.8 Use of Couplers and Threading

Cutting a thread in a MA rebar and a QT rebar will yield different results. Because the MA bar has the same strength and ductility properties across its cross section the loss in strength of the bar is proportional to the amount of steel lost in the thread cutting operation. A QT bar on the other hand gains its strength from the hard quenched casing so cutting a thread into this outer casing will mean that the loss in strength is not proportional to the amount of steel which is removed.

“Threading of quench and tempered bar removes some to all the Hardened outer layer resulting in a disproportionate loss of strength.”

4.9 Performance at Elevated Fire Temperatures

Reinforced concrete buildings are exposed to the elevated temperatures during a fire event. Most often the elevated temperatures exceed 500 Degrees Centigrade. Unfortunately this is also about the tempering temperature of QT / TMT rebars. Thus, prolong exposures to elevated temperatures could result in retempering of the outer skin resulting in reversion to the strength of the core steel which is vastly reduced.

Thus, accelerated failure of the RC Building frame during a fire is more likely for a building designed using the Yield and tensile Properties of a QT / TMT rebar whether knowingly or unknowingly.

All the foregoing considerations point to the serious problems associated with the use of QT/TMT rebars where welding, bending, heating, threading and galvanizing temperatures are involved.

What is more compelling is the degraded performance during Cyclic Loading conditions in an Earthquake.

5 SEISMIC PERFORMANCE CONSIDERATIONS

Although, the foregoing are important considerations, the main argument against the use of QT/TMT Rebars in Seismic Zone 4 is its behavior under cyclic loading. Studies in several parts of the world notably Italy, New Zealand and Australia etc have pointed to the dangers associated with the use of QT / TMT rebars under Cyclic loading particularly in Seismic Zone 4.

These do not even include the unsuitability of the same bars when welded under cyclic loading which as the MIRDC study shows, indicate a very limited elongation of the rebars when welded and subjected to static tensile tests.

In a study by Macchi [Ref. 2] a large full scale RC specimen was subjected to cyclic loading to check the ductility of Traditional Steel and TMT rebars conforming to Eurocode EC 8 Seismic detailing.

We quote the experimental results as follows:

“With only one exception, all steel A8 (A8 referring to QT/TMT rebars) specimens failed when tested according to sequences….. In fact, all steel A8 reinforcing bars failed before the end of the Test. In many cases, they failed during the first cycle at the maximum required displacement”

“On the contrary, specimens built with steel Fe (referring to Standard MA Steel rebars) behaved satisfactorily.”

“Quite different behavior in the RC Specimens was observed with the two kinds of steel:

*With steel A8 (QT/TMT), plastic strains of the bars were concentrated in a very limited vertical region of the specimen. The high local curvature necessary for the required displacement at the top caused a considerable deterioration, leading to destruction of the concrete cover. The lack of concrete cover allowed the bars in compression to buckle. The bars then failed in tension under reverse action.”

*With steel Fe, the plastic deformation spread for a considerable length along the specimen because of the high strain hardening value fu / fy, local curvature was smaller, the concrete cover remained intact and the bars did not fail. The RC member therefore sustained higher top displacement”

6 CONCLUSION AND RECOMMENDATIONS

There is indeed a Clear and present Danger associated with the use of QT / TMT Rebars in Seismic Zone 4 which encompasses the majority of the Philippine Islands except Palawan.

As shown on this paper, even international Codes such as the New Zealand Code and the Australian Standards prohibit Welding, Heating, Bending, Threading and even Tack welding of QT / TMT rebars. Welding can be used but special electrodes which “cost 7 Times more 10] ” are required with the necessary corresponding welding skills, but even then a reduction in the strength is required which prevent its use in Seismic Zone 4.

We again cite in its entirety the prohibitions in the New Zealand Standards as follows:

NZ Standard 3101:2006 Concrete Structures Part 2

Section C-5.8.2 In Line quenched and tempered steel bars

Welding of in-line quenched and tempered bars can have detrimental effects on the strength and ductility of the bars and associated connection. AS 3600 requires designers to assume that the strength of such reinforcement has a design strength of 250 Mpa when raised to the temperature associated with welding, Galvanizing or hot bending. Such a requirement is considered inappropriate in a seismically active country where concentration of yielding at a weld position would be undesirable and could result in brittle failure.

So where is the place of QT / TMT is rebars in our practice?

The answer is:

ONLY IN APPLICATIONS WHERE THE ABOVE PROHIBITIONS ARE NOT APPLICABLE AND CERTAINLY NOT FOR HIGH RISE BUILDINGS IN ZONE 4.

7. THE ROAD AHEAD

The structural Engineering Profession and Consultants in General can no longer postpone action on the CONTINUED USE unqualified use of QT / TMT rebars for high rise buildings in Seismic Zone 4.

We must encourage the Philippine Steel Industry through the PISI to again bring the MA rebars in the market by categorically specifying this in our design and categorically stating that QT / TMT rebars are not to be supplied as an alternative in Seismic Zone 4 Building Designs.

The weak argument is that it will increase the cost of rebars. However, the author asks: Is there a Price on Public Safety?

If we do not do this and with the Publication of this Paper and similar papers, the Engineering community is now formally informed of the dangers associated with the continued use of QT / TMT rebars in Seismic Zone 4.

REFERENCES

- Macchi G. “Ductility Requirements for Reinforcement under Eurocodes.” Structural Engineering International April 1996.

- New Zealand Standard NZS 3101-2006 Amendment 1 –Concrete Structures Standard The Design of Concrete Structures.

- Jitendra K Bothara “Comparing Seismic® QT and Seismic® MA, High Strength Bars and Design Considerations”.

- PISI Letter of Mr Wellington Tong – President to ASEP

- Fudolig,A et al “Characterization of Locally-Manufactured Quenched tempered and Self Tempered Reinforcing Steel Bars” MIRDC Feb 1999.

- New Zealand Department of Building and Housing “Report on Grade 500 E Reinforcement” July 2005 Wellington NZ

- Bureau of Product Standards, DTI “PNS 49:2002 Steel Bars for Reinforced Concrete- Specification”

ABOUT THE AUTHOR

Emilio M. Morales CE, Principal of EM2A Partners & Co., Master of Science in Civil Engineering, Carnegie Mellon University, Pittsburgh Pa., Fellow ASCE, PICE, and ASEP and a PhD Candidate at the Asian Institute of Technology, Bangkok Thailand.

Formerly Senior Lecturer, UP Graduate Division, School of Civil Engineering, Diliman, Quezon City. He can be contacted at EM2A Partners & Co., No. 17 Scout de Guia corner Scout Reyes Streets, Diliman, Quezon City. Telephone Nos. 371-1804 & 06. E-mail address: em2apartners@gmail.com.

1] Principal EM2A Partners, MS in Civil Engineering , Carnegie Mellon University, Pittsburgh Pa., Fellow PICE, ASEP and ASCE. PhD Candidate Asian Institute of Technology, Bangkok Thailand, Formerly Senior Lecturer, UP Graduate Division, School of Civil Engineering, Diliman.

2] Macchi G. “Ductility Requirements for Reinforcement under Eurocodes.” Structural Engineering International April 1996.

3] Jitendra K Bothara “Comparing Seismic® QT and Seismic® MA, High Strength Bars and Design Considerations”.

4] New Zealand Standard NZS 3101-2006 Amendment 1 –Concrete Structures Standard The Design of Concrete Structures.

5] Macchi G., “Ductility Requirements for Reinforcement under Eurocodes.” Structural

6] Philippine Iron and Steel Institute.

7] PISI Letter of Mr Wellington Tong – President to ASEP

8] Fudolig,A et al “Characterization of Locally-Manufactured Quenched tempered and Self Tempered Reinforcing Steel Bars” MIRDC Feb 1999.

9] New Zealand Department of Building and Housing “Report on Grade 500 E Reinforcement” July 2005 Wellington NZ

10] Professional Waiver kindly granted by Dr. Fudolig of MIRDC.

11] Fudolig A. et al – “Characterization of Locally-Manufactured Quenched Tempered and Self Tempered Reinforcing Steel Bars” MIRDC Feb 1999.

12] Bureau of Product Standards, DTI “PNS 49:2002 Steel Bars for Reinforced Concrete- Specification”

Download A Clear and Present Danger 2 – The Use of QT or TMT Rebars in Seismic Zone 4